Our Sponsors

Our Collaborators and Partners

Sponsored Projects

Legislative-Citizen Commission on Minnesota Resources (LCCMR), LiDAR technology preventing wildlife fatalities from wind turbines, Period 2024-26, $0.53M.

NASA Early Career, Physics-based formulation of tailored ionic liquids for spacecraft thermal control, Period 2023-26, $0.6M.

Office of Naval Research Young Investigator, Plasma-assisted sensing and control of combustion instabilities in lean high-pressure turbulent flames, Period 2023-26, $0.75M.

ARPA-E, Plasma‐assisted in‐situ reforming of flare gases to achieve near‐zero methane emissions, Period 2022-25, $2.4M.

ARPA-E, Reducing emission of methane through advanced radical kinetics and adaptive burning in large engines (REMARKABLE), Period 2022-25, $0.5M.

Department of Energy, Plasma-assisted pre-chamber ignition system for highly dilute stoichiometric heavy-duty natural gas engines, Period 2022-25, $2.1M.

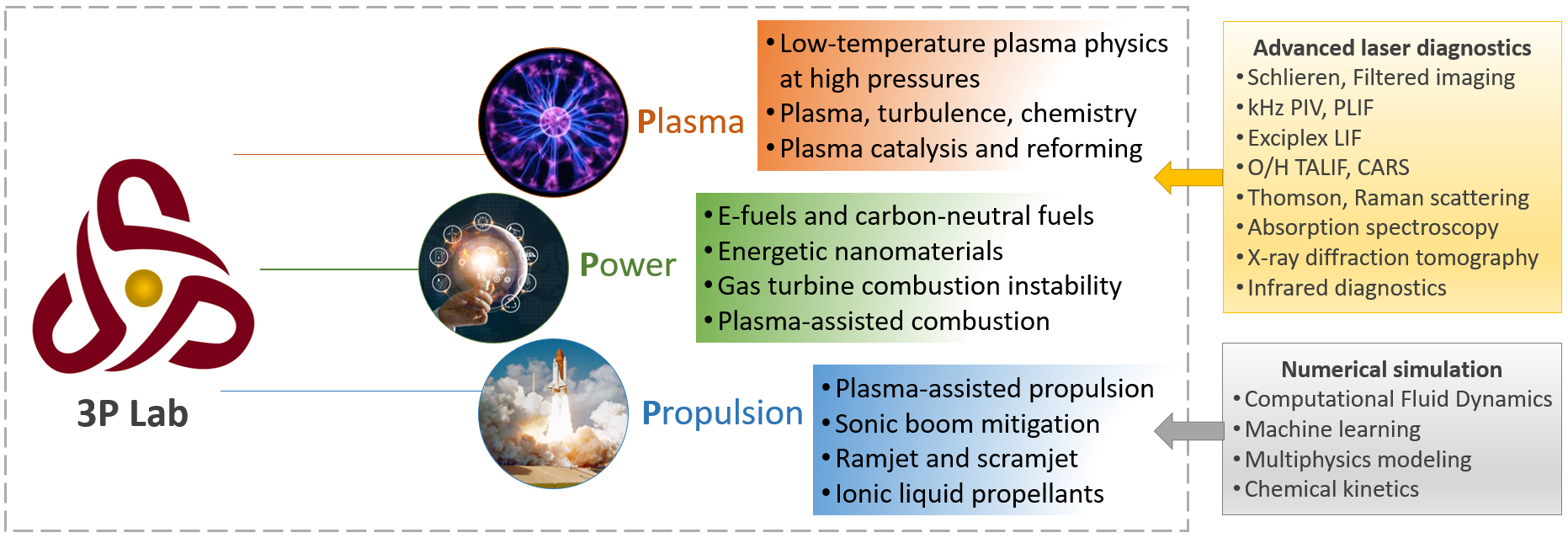

Research Topics

Fundamentals of Low-Temperature Plasma

Low-temperature plasma has the potential to bring radical advancement in existing technologies in energy, microelectronics, automotive, aviation, environment, and manufacturing. The field of low-temperature plasma is exceptionally interdisciplinary with numerous unsolved grand scientific questions. For example, unpredictable plasma streamer branching and filamentation processes in high-pressure gases and liquids, surprising collective motion exhibited by plasma, stochastic and turbulent behavior of plasma discharge, plasma instability, plasma-material interaction, generation of selective radicals and charged species such as O3, OH, atomic oxygen, etc. to name a few. 3P Lab research examines low-temperature plasma behavior at high-pressure, transitions between different plasma regimes, and underlying physical governing mechanisms.

Plasma in Transportation and Environmental Applications

The unique characteristics of low-temperature plasma can radically change existing engine operations. For example, low-temperature plasma ignition for future mixed-mode combustion, plasma actuators for near-wall flow controls, plasma remediation of greenhouse and toxic engine emission gases, and plasma trap for hazardous particulate matter. Plasma-assisted ignition has several advantages over conventional spark ignition systems, including greater control of ignition delays and the location of the ignition kernel, faster ignition facilitated by radicals and charged species, virtually zero spark plug erosion. 3P Lab is currently developing a fully functional prototype of a plasma igniter.

A fast and accurate actuation is required to control high-velocity high Reynolds number flows. 3P Lab searches for innovative ways such as DC discharge, distributed corona discharge, transient nanosecond discharge, smart materials for state-of-the-art plasma electrode design, etc. to effectively control subsonic, transonic, and supersonic flows. Emissions from automotive and gas turbine engines are a significant contributor to climate change. Low-temperature plasma reactors can be used as a particulate trap (electrostatic precipitation) or as a NOx converter (plasma catalysis). 3P Lab explores plasma-catalytic chemistry and electromagnetic discharge behavior – areas that demand fundamental understandings. Low-temperature plasma research can potentially contribute to leaner engine operation with a reduction in NOx and particulate matter, higher pressure engine operation, and more reliable hardware systems.

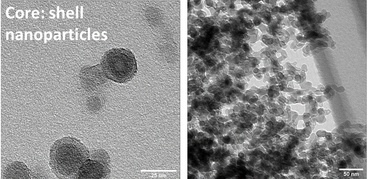

Microscale Power Generation and Nanoenergetics

The miniaturization of electromechanical devices and the resulting need for a micropower generation with low-weight, long-life devices have provided opportunities for research on nanoenergetic materials. The biggest challenge in microscale-power production is how to sustain combustion at microscale since the length scale is comparable to the quenching distance. A fundamental understanding of flame dynamics on such a small scale is essential to the development of micro-power generators. Nanoenergetic materials offer much higher energy densities and faster energy release rate – attractive for various propulsion and energy-conversion applications. Through experiments and simulations, 3P Lab performs fundamental research on nanofluids and nanoenergetics.

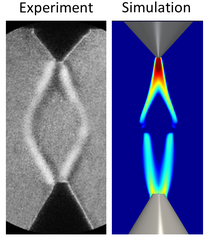

Scramjet Liquid Fuel Injection Optimization

In supersonic combustion ramjets (scramjets), combustion occurs at speeds of around Mach 2 - 3. These high-speed flows provide only a few milliseconds for the liquid fuel to break up, atomize, and mix with the crossflow of air. Poorly mixed fuel leads to unstable and inefficient combustion, ultimately harming scramjet performance. 3P lab utilizes a miniature supersonic wind tunnel with a range of Mach 1 - 3.5 to investigate this liquid jet in supersonic crossflow problem, and a 1” x 1” Mach 2 wind tunnel is being designed for future research. Novel plasma technologies are being developed to assist the atomization process of the fuel and thus enhance the overall efficiency of scramjets. Equilibrium and non-equilibrium plasma configurations are being tested to better understand their effect on the penetration height, frequency of breakup, and level of mixing of the liquid jet.

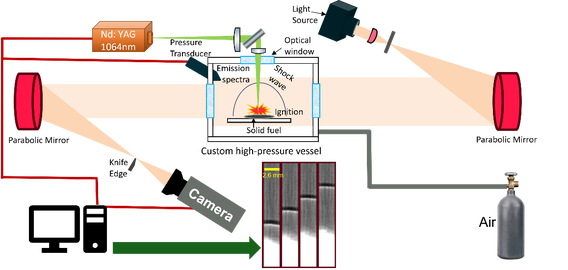

Laser-Induced Air Shock from Energetic Materials (LASEM)

Laser-induced Air Shock from Energetic Materials (LASEM) is an experimental technique utilized for characterizing the reactive behavior of energetic materials on a laboratory scale. It presents a cost-effective and efficient alternative to full-scale detonation testing, as it requires significantly lesser quantities of fuel (in the order of milligrams) compared to large-scale detonation experiments, which demand several hundred grams to kilograms of energetic materials/fuels.

To conduct LASEM experiments, we employ a high-pressure, optically accessible, custom-built constant volume vessel. A nanosecond-pulsed laser with a pulse width of 6 ns and a wavelength of 1064 nm is focused on a glass slide uniformly coated with metal nanoparticles. High-speed filtered imaging is employed to study the laser-induced shock dynamics and combustion processes of these metal nanoparticles. The propagation speed of the laser-induced shock wave is recorded using high-speed Schlieren imaging at a frame rate of a million frames per second. Similarly, optical emission spectroscopy is deployed to measure plasma electron number density, temperature, and atomic and molecular species emissions to decouple the plasma chemistry from combustion and their influence on shock speed.

Gas Turbine Combustion Instabilities

In order to meet modern emission standards, many gas turbine engines use lean premixed fuel. This lowers NOx emissions, but comes at the cost of more unstable combustion. Variations in heat release can couple with the acoustics of the combustor and result in growing pressure oscillations. Also, instabilities occur near the lean blowout limit of the flame. Many passive methods for lessening pressure variations, such as the use of a Helmholtz resonator, have been studied extensively. 3P Lab is focused on investigating a specific active method for stabilizing the combustion: plasma. Plasma assisted combustion is a growing field and multiple recent studies have been performed looking into how it can be used in gas turbines with a swirl stabilized flame. 3P Lab is developing a lab-scale swirl stabilized gas turbine combustor that can reach pressures up to 10 bar. The ultimate goal is to use plasmas to detect the onset of instabilities and offset them with nanosecond pulsed discharges. Various swirlers and electrode configurations will be explored.

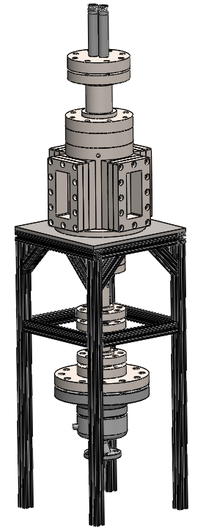

Investigating pre-chamber combustion in an optically accessible RCEM

The lean-burn strategy is one of the most promising solutions for emission reductions due to the increased specific heat ratio of the charge and reduced heat losses through walls. However, conventional spark ignition (SI) engines suffer from poor combustion stability and high cycle-to-cycle variations in lean operation. Thus, pre-chamber combustion (PCC) is an advanced combustion strategy that enhances ignition energy and provides distributed ignition sites by igniting a small volume of fuel/air mixture in a pre-chamber.

Advanced Optical Diagnostics, Laser Spectroscopy, and Novel Imaging

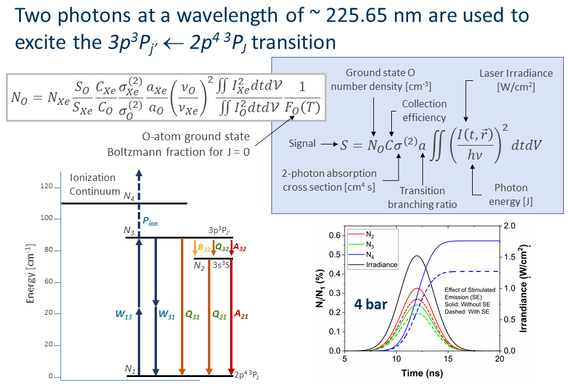

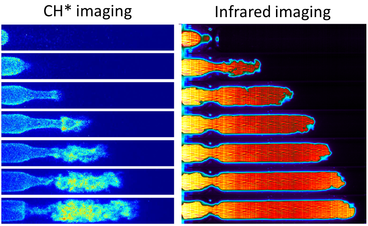

3P Lab is developing various laser diagnostics, including Laser-Induced Fluorescence (LIF) of OH and CH radicals, Particle Image Velocimetry (PIV), Laser-Induced Incandescence (LII) of soot, Two-photon Absorption LIF (TALIF) of atomic oxygen and hydrogen, Coherent Anti-Stokes Raman Scattering (CARS), absorption spectroscopy, Raman and Thomson scattering, high-speed schlieren and shadowgraph, etc., to reacting and non-reacting environment. Additionally, 3P Lab’s research interest is to develop Laser-Induced Exciplex Fluorescence (LIEF) for time-resolved vapor and liquid phase measurement, X-ray diffraction tomography for high-pressure flow imaging without requiring optical accessibility, kHz PIV-PLIF to explore high-speed transient events, infrared laser diagnostics for species detection, Thomson scattering for low-temperature plasma research. These laser diagnostic techniques are instrumental in understanding complex flow dynamics and energy systems.

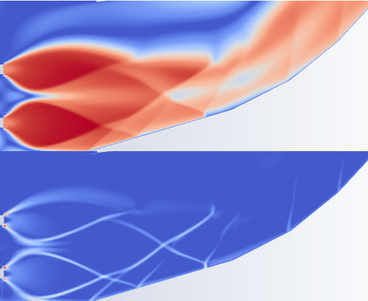

Numerical Modeling of Flow, Reaction and Plasma

3P Lab is interested in performing high-fidelity numerical simulations of reacting and non-reacting flows. The Lab uses commercial CFD solvers like CONVERGE, ANSYS, COMSOL and collaborates with other computational groups for Large-Eddy Simulation (LES) and Direct Numerical Simulation (DNS). LES and DNS provide helpful insights in finding local scalar structures and reaction rates to better understand the turbulence-chemistry interactions. The goal of the 3P Lab is to develop a robust mathematical framework and numerical schemes to extend the capability of the current numerical simulation codes to Petascale and future Exascale.

The simulation methods to understand low-temperature plasma physics are continuously evolving with topics such as appropriate treatment of the sheath region, electron production mechanism from non-refractory cathodes still remain a subject of debate. 3P Lab collaborates with modeling groups at National Labs and Universities to broaden the understanding of non-equilibrium regions of the plasma such as sheaths and the arc fringes, collisional–radiative models, interactions between the plasma and electrodes, the coupling of the plasma model to the material property model, etc.

Future Research Topics

Plasma Propulsion

Plasma-based space propulsion systems are highly efficient compared to existing chemical propulsion and can reduce fuel requirements by a factor of 100. Plasma thrusters are best suited for deep space exploration. However, the reliability and longevity of the thruster due to the harmful interactions between reactive plasmas and complex thruster surface is one of the major challenges in plasma propulsion. One possible solution to this problem is to use electrodeless systems where the plasma is created and accelerated by the action of electromagnetic waves rather than by the presence of physical electrodes immersed in the flow. 3P Lab aims to develop a lightweight plasma thruster that can handle increasing levels of power in a relatively small package.

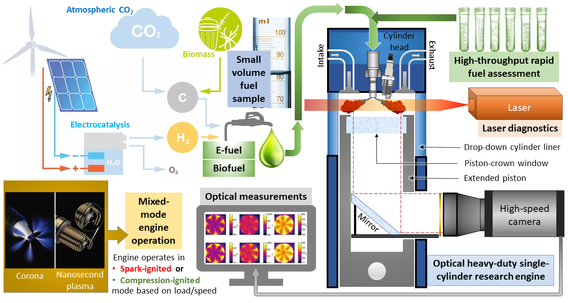

Carbon-Neutral Synthetic E-Fuels and Biofuels

Clean carbon-neutral ‘designer’ synthetic fuels produced from renewable sources emit ‘zero’ net greenhouse gas emissions. Currently, 3P Lab is designing a unique instrument, high-throughput, optical research engine facility that will help discover new E-fuels and biofuels. The most unique feature of the optical engine is the capability of rapidly evaluating a large number of E-fuel samples of milliliter volumes. No existing facility is capable of performing rapid characterization of such small volume fuel samples. The high-quality optical data will provide a fundamental understanding of the complex chemistry, turbulence, and fluid dynamics processes. The instrument will be equipped with advanced plasma and corona ignition system to enable mixed-mode operation. The proposed instrument’s unique capabilities will allow a transformative platform for researchers to create and optimize innovative carbon-neutral fuel molecules that will lead to decarbonizing the transport sector and meet the stringent climate goals.

Flame Stabilization in Ramjet and Scramjet

3P Lab investigates flame stabilization in ramjet and scramjet combustors for supersonic air vehicles. At flight speeds beyond Mach 6, air entering the combustor must be supersonic to avoid excessive pressure loss, overheating and dissociation of reactants. At such a high speed, the typical residence time inside the combustor is on the order of few milliseconds. Fuel injection, mixing, and combustion within such a short time is a challenge. Besides shorter chemical timescale, combustion instability poses a major challenge in such propulsive devices. 3P Lab intends to investigate active and passive control of combustion instability in a gas turbine, ramjet, and scramjet using experiments and multi-physics simulations.